Gravity conveyors

Conveyor systems, rollers, packages and custom solutions

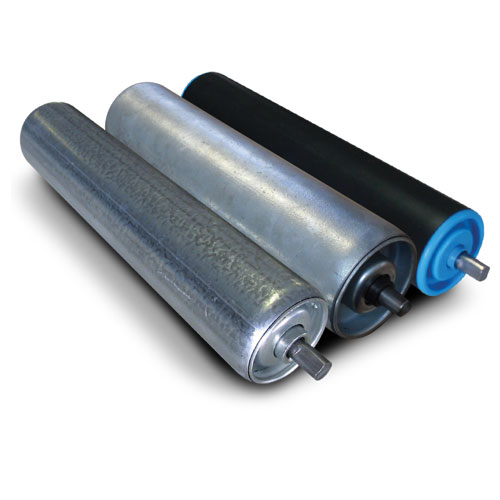

We can supply conveyor systems or components to suit your application

Conveyor systems can be a crucial part of a manufacturing or distribution process. They need to be able to move products quickly, quietly and efficiently.

Browse our wide range of options below, or get in touch with our product specialists.

Our range

Suitable for most industries

Gravity conveyor systems are widely used across various industries due to their simplicity, cost-effectiveness, and efficiency. Some of the industries that commonly utilise gravity conveyor systems include: Distribution, manufacturing, automotive, retail/eCommerce, aerospace, pharmaceuticals, textiles, warehousing, parcel handling processing, packaging, warehouses, shipping departments, and assembly lines.